Shackleton WR963

Forum rules

One thread per aircraft/project please.

One thread per aircraft/project please.

Re: Shackleton WR963

Cheers!

I have a load of photos to post from last Saturday's run, but we told Airbase we'd hold off putting them out on the internet until Friday's opening.

I'll try and keep you all updated as best I can.

Regards,

Rich

I have a load of photos to post from last Saturday's run, but we told Airbase we'd hold off putting them out on the internet until Friday's opening.

I'll try and keep you all updated as best I can.

Regards,

Rich

-

Richw_82 - Lockheed F-104 Starfighter

- Posts: 290

- Joined: Tue Apr 19, 2011 9:57 pm

Re: Shackleton WR963

Thanks I/we'd like that!

Fly fast jets and/or C130s over my house please, I'm bored!

BUCCANEER TO THE SKY!

BUCCANEER TO THE SKY!

-

Olicat - Lockheed Constellation

- Posts: 4462

- Joined: Sun Aug 22, 2010 5:59 pm

- Location: That way! ↓

- Also Known As: Bullet

Re: Shackleton WR963

Xplumberlives wrote:Welcome Rich your input and photos will be most welcome!

What he said

Really looking forward to your photos

RAF Lincolnshire photo albums.

https://plus.google.com/photos/11759264 ... 663/albums

http://raflincolnshire.blogspot.co.uk/

https://plus.google.com/photos/11759264 ... 663/albums

http://raflincolnshire.blogspot.co.uk/

-

Hihonyr8811 - Airbus A380

- Posts: 3784

- Joined: Fri Oct 17, 2008 7:35 pm

- Location: Lincoln

- Also Known As: Lincoln, Hiho, Helen

Re: Shackleton WR963

Welcome to Iconic, Rich.

I'll try to be there on Friday.

I'll try to be there on Friday.

Sooty

One Olympus 301 has twice the power of a complete F1 starting grid.

XM655 has four of them, all serviceable.

When we make noise, WE MAKE NOIZE ! !

XM655 has four of them, all serviceable.

When we make noise, WE MAKE NOIZE ! !

-

Sooty655 - Moderator

- Posts: 8870

- Joined: Sat Jan 03, 2009 9:17 pm

- Location: Weedon, Northants

Re: Shackleton WR963

A brief look at how far this old cold war beastie has come in the last 12 months. This was April last year - we hadn't ran the engines since 27 Jan 2010, due to an oiling problem causing horrendous camshaft wear (some of which is still left to rectify)

5 Feb 2011 saw two engines fit to go. Attempts at getting the Coastal scheme done had been stalled by the weather, but at least we were running now after 13 months of silence.

The long term aim is to get her back to the condition she enjoyed in 2008, when she got out on the runway for a fast taxi. If we can achieve that by the end of the year, we'll be very happy, given that this is WR963's 20th year in retirement.

Regards,

Rich

5 Feb 2011 saw two engines fit to go. Attempts at getting the Coastal scheme done had been stalled by the weather, but at least we were running now after 13 months of silence.

The long term aim is to get her back to the condition she enjoyed in 2008, when she got out on the runway for a fast taxi. If we can achieve that by the end of the year, we'll be very happy, given that this is WR963's 20th year in retirement.

Regards,

Rich

-

Richw_82 - Lockheed F-104 Starfighter

- Posts: 290

- Joined: Tue Apr 19, 2011 9:57 pm

Re: Shackleton WR963

Rich, you are a Godsend to those of us who

LUV prop aircraft!

She is a Loverly Old Crate, and I look forward

to anything you care to send us!

Dan4th

LUV prop aircraft!

She is a Loverly Old Crate, and I look forward

to anything you care to send us!

Dan4th

I like to do my planning retroactively!

-

Dan4th - Boeing B-52 Stratofortress

- Posts: 14733

- Joined: Thu Nov 06, 2008 9:42 pm

- Location: Bangor, Maine, USA

- Also Known As: Token Murkin

Re: Shackleton WR963

Mackrick wrote:Nice photos. Would love to see more please....

here here I will second that..................................

-

Sploosher - BAE Hawk

- Posts: 2993

- Joined: Sun Jan 03, 2010 12:31 pm

- Also Known As: jangor

Re: Shackleton WR963

Awesome, I'll post some more then. I'm sure by now those of you that are pretty sharp with a computer will have found my photobucket account anyway, but I'll crack on.

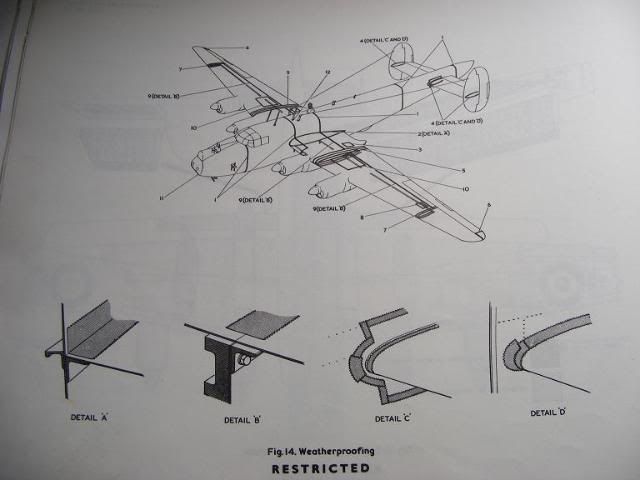

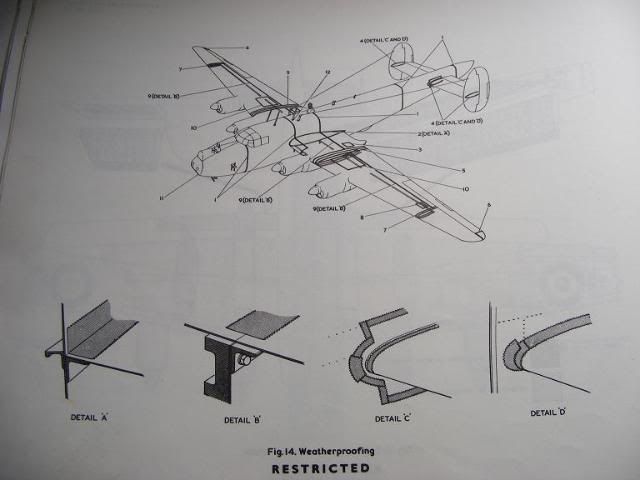

The aircraft's exterior was in a bit of a state when I first got to Coventry It had been repainted around 10 years ago into 38 Sqn colours, and by now it was ready for doing again. Other bits that had not been touched were now begging for attention too, the sealing tapes used to cover joints were all rotten and peeling. The aircraft was leaking like a sieve, which had a knock on effect on a number of other systems, the worst being when it got into the fuel system.

This is what we started with:

This is the wing cleaned and with new sealing tapes applied:

Which then looks really great when you get a coat of BS381C 637 medium sea grey on it.

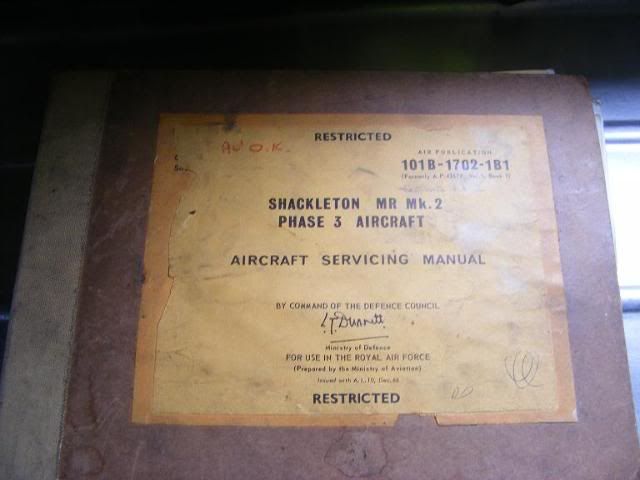

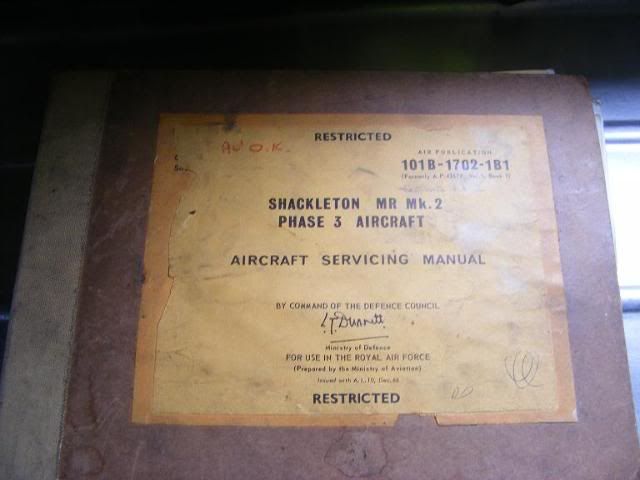

Thankfully we have all the manuals, like these:

We've also got ALL the design drawings for the Shackleton, which amounts to some 16 tons of paperwork. After getting the sealing done, we had some scaffolding erected to work from This brought about some really amusing internet rumours like the undercarraige being removed, or that we were breaking 963 up.

The white scheme kept going on, but the weather stalled it. We decided to hold off through winter and negotiated with Airbase for some hangar time to finish the job. We got most of the fuselage done in white in time for the "Help For Heroes" fly in at Coventry in September. WR963 saw 500 visitors in one day tour her.

While we were waiting on winter getting out of the way, we set about the engines. None of our group have the experience to build the missing prop up for No 2 engine, but we could handle the onboard pre-oiling system. This is a bespoke system designed by one of our engineers. It uses an American made Oilamatic pump with a take off from the main oil feed, to pump oil at high pressure into the oil galleries prior to starting. Originally you had to remove all the cowlings and various blanking plugs. Now the engine is turned manually for four minutes, with the oilers switched on in the engineers panel. No fuss, no mess, no problem.

The oil tank is the big one in the middle You can't see the oil feed but the plumbing at this side is all very basi. It's hard to believe they slung a Rolls Royce Viper jet engine in there on the MR3, as theres so little room. The pumps are activated by switches and wiring that is a redundant leftover system for oil dilution.

The idea was to cut down on cam wear. The first 10 seconds of running is critical.. if a Griffon shows no oil pressure after that you must shut it down. Even for those 10 seconds though, there is little oil to the top end, so the cams rely on what they have until the pressure comes up. Ours hadn't been getting fed.

By the time we had the system in place there was snow on the floor.

Due to cold temperatures, oil like treacle, and batteries that weren't interested in providing great voltages in the cold it didn't work. We waited for the snow to go away, then came back in January and tried again. A few parts were found to have been supplied with incorrect internal dimensions acting as restrictors. We drilled them out and were rewarded with great flows of oil at the cams.

Now at last we could run engines... with 5 Feb being the day WR963 growled again.

Regards,

Rich

The aircraft's exterior was in a bit of a state when I first got to Coventry It had been repainted around 10 years ago into 38 Sqn colours, and by now it was ready for doing again. Other bits that had not been touched were now begging for attention too, the sealing tapes used to cover joints were all rotten and peeling. The aircraft was leaking like a sieve, which had a knock on effect on a number of other systems, the worst being when it got into the fuel system.

This is what we started with:

This is the wing cleaned and with new sealing tapes applied:

Which then looks really great when you get a coat of BS381C 637 medium sea grey on it.

Thankfully we have all the manuals, like these:

We've also got ALL the design drawings for the Shackleton, which amounts to some 16 tons of paperwork. After getting the sealing done, we had some scaffolding erected to work from This brought about some really amusing internet rumours like the undercarraige being removed, or that we were breaking 963 up.

The white scheme kept going on, but the weather stalled it. We decided to hold off through winter and negotiated with Airbase for some hangar time to finish the job. We got most of the fuselage done in white in time for the "Help For Heroes" fly in at Coventry in September. WR963 saw 500 visitors in one day tour her.

While we were waiting on winter getting out of the way, we set about the engines. None of our group have the experience to build the missing prop up for No 2 engine, but we could handle the onboard pre-oiling system. This is a bespoke system designed by one of our engineers. It uses an American made Oilamatic pump with a take off from the main oil feed, to pump oil at high pressure into the oil galleries prior to starting. Originally you had to remove all the cowlings and various blanking plugs. Now the engine is turned manually for four minutes, with the oilers switched on in the engineers panel. No fuss, no mess, no problem.

The oil tank is the big one in the middle You can't see the oil feed but the plumbing at this side is all very basi. It's hard to believe they slung a Rolls Royce Viper jet engine in there on the MR3, as theres so little room. The pumps are activated by switches and wiring that is a redundant leftover system for oil dilution.

The idea was to cut down on cam wear. The first 10 seconds of running is critical.. if a Griffon shows no oil pressure after that you must shut it down. Even for those 10 seconds though, there is little oil to the top end, so the cams rely on what they have until the pressure comes up. Ours hadn't been getting fed.

By the time we had the system in place there was snow on the floor.

Due to cold temperatures, oil like treacle, and batteries that weren't interested in providing great voltages in the cold it didn't work. We waited for the snow to go away, then came back in January and tried again. A few parts were found to have been supplied with incorrect internal dimensions acting as restrictors. We drilled them out and were rewarded with great flows of oil at the cams.

Now at last we could run engines... with 5 Feb being the day WR963 growled again.

Regards,

Rich

http://www.avroshackleton.co.uk/

http://www.facebook.com/ShackletonReturnToFlight

Follow our efforts to get a Shackleton back in the air!

http://www.facebook.com/ShackletonReturnToFlight

Follow our efforts to get a Shackleton back in the air!

-

Richw_82 - Lockheed F-104 Starfighter

- Posts: 290

- Joined: Tue Apr 19, 2011 9:57 pm

Re: Shackleton WR963

Rich:

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Dan4th

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Dan4th

I like to do my planning retroactively!

-

Dan4th - Boeing B-52 Stratofortress

- Posts: 14733

- Joined: Thu Nov 06, 2008 9:42 pm

- Location: Bangor, Maine, USA

- Also Known As: Token Murkin

Re: Shackleton WR963

Great report.

Jim.

Jim.

We can't all be heroes because somebody has to sit on the curb and clap as they go by

http://www.flickr.com/photos/lucas1860/?saved=1

-

Lucas1860 - Boeing C-17 Globemaster III

- Posts: 1425

- Joined: Tue Apr 13, 2010 5:18 pm

- Location: Barnsley South Yorkshire

- Also Known As: @Aviation1860

Re: Shackleton WR963

That was superb. Keep them coming. I am only just catching up properly after a busy week so thanks for all the pics and info and welcome to IA Rich

Kev

-

Jigsaw - Boeing 747

- Posts: 6456

- Joined: Thu Feb 05, 2009 1:58 pm

- Location: Scunthorpe

- Also Known As: photo_lincs

Re: Shackleton WR963

Absolutely superb ! More soon please

-

Kermit - Boeing B-29 Superfortress

- Posts: 762

- Joined: Thu Sep 23, 2010 7:03 pm

- Location: Northamptonshire

- Also Known As: jocelyn

Re: Shackleton WR963

This picture does not do her justice as she is simply stunning in the flesh

I shall post my vid up of the run asap

I shall post my vid up of the run asap

Rain God Mod

-

Cluny - Moderator

- Posts: 2868

- Joined: Fri Oct 03, 2008 6:19 pm

- Location: Bicester

- Also Known As: Blizzard the watcher

Re: Shackleton WR963

Cluny wrote:I shall post my vid up of the run asap

Yes, please.

I missed it.

I was doing the jobs I missed due to the Mountain Rescue Team call-out.

I was doing the jobs I missed due to the Mountain Rescue Team call-out.

Sooty

One Olympus 301 has twice the power of a complete F1 starting grid.

XM655 has four of them, all serviceable.

When we make noise, WE MAKE NOIZE ! !

XM655 has four of them, all serviceable.

When we make noise, WE MAKE NOIZE ! !

-

Sooty655 - Moderator

- Posts: 8870

- Joined: Sat Jan 03, 2009 9:17 pm

- Location: Weedon, Northants

Re: Shackleton WR963

Sooty655 wrote:Cluny wrote:I shall post my vid up of the run asap

Yes, please.

I missed it.I was doing the jobs I missed due to the Mountain Rescue Team call-out.

Well you missed a CRACKER!

Cluny's Video camera didn't shut down once, he's got some super footage and I will add my Stills when I get a chance tomorrow!

Looking forward to the day (SOON) when they get the fourth engine up and running!

"All modern aircraft have 4 dimensions: span, length, height and politics.

TSR-2 simply got the first 3 right. ”

— Sir Sydney Camm

TSR-2 simply got the first 3 right. ”

— Sir Sydney Camm

-

Xplumberlives - Boeing B-17 Flying Fortress

- Posts: 41162

- Joined: Wed Oct 01, 2008 9:27 pm

- Location: Close to a former Harrier Airfield

- Also Known As: ROCKETMAN

Re: Shackleton WR963

Great pictures, brings back a few memories, especially the griffons, used to sit up there, cowlings hinged, checking out mag problems, drying off wet denims as the aircraft had just landed. 8 Squadron 74-76, Lossiemouth.

if it's working, leave well alone

-

LightningMk6 - Piper J-3 Cub

- Posts: 59

- Joined: Sun Mar 06, 2011 5:35 pm

- Location: Louth Lincs

-

Cluny - Moderator

- Posts: 2868

- Joined: Fri Oct 03, 2008 6:19 pm

- Location: Bicester

- Also Known As: Blizzard the watcher

Re: Shackleton WR963

Absolutely fantastic vid Paul! Can't imagine that beast being quiet either!

Fly fast jets and/or C130s over my house please, I'm bored!

BUCCANEER TO THE SKY!

BUCCANEER TO THE SKY!

-

Olicat - Lockheed Constellation

- Posts: 4462

- Joined: Sun Aug 22, 2010 5:59 pm

- Location: That way! ↓

- Also Known As: Bullet

Re: Shackleton WR963

what a great set of images that is.............................

Will definately have to make a trip to see this beauty roar................

Will definately have to make a trip to see this beauty roar................

-

Sploosher - BAE Hawk

- Posts: 2993

- Joined: Sun Jan 03, 2010 12:31 pm

- Also Known As: jangor

Re: Shackleton WR963

I like to do my planning retroactively!

-

Dan4th - Boeing B-52 Stratofortress

- Posts: 14733

- Joined: Thu Nov 06, 2008 9:42 pm

- Location: Bangor, Maine, USA

- Also Known As: Token Murkin

Re: Shackleton WR963

Glad you all enjoyed the run.

Cluny, that video is excellent, thanks for posting it.

I didn't manage to get any photo's of my own as I was engineer for the run, so was a bit busy. I also had the Mayor of Coventry stood at the side of me - which did nothing for my nerves given that this was my first time on the engineers panel after training!

Lucky for us, the aircraft behaved wonderfully. None of the coughing, or mag drop on No 3 that we had on last Saturday's practice. The whole crew is pleased with their efforts.

We ran out of time with the prop... eagle eyed visitors will have noticed it all stashed in a corner of the hangar, waiting for whoever has been tasked to build it. We're hoping it will be done in time for the next run on the 4th May, but the engine will require de-inhibiting and testing before we run it with the others publicly.

Regards,

Rich

Cluny, that video is excellent, thanks for posting it.

I didn't manage to get any photo's of my own as I was engineer for the run, so was a bit busy. I also had the Mayor of Coventry stood at the side of me - which did nothing for my nerves given that this was my first time on the engineers panel after training!

Lucky for us, the aircraft behaved wonderfully. None of the coughing, or mag drop on No 3 that we had on last Saturday's practice. The whole crew is pleased with their efforts.

We ran out of time with the prop... eagle eyed visitors will have noticed it all stashed in a corner of the hangar, waiting for whoever has been tasked to build it. We're hoping it will be done in time for the next run on the 4th May, but the engine will require de-inhibiting and testing before we run it with the others publicly.

Regards,

Rich

http://www.avroshackleton.co.uk/

http://www.facebook.com/ShackletonReturnToFlight

Follow our efforts to get a Shackleton back in the air!

http://www.facebook.com/ShackletonReturnToFlight

Follow our efforts to get a Shackleton back in the air!

-

Richw_82 - Lockheed F-104 Starfighter

- Posts: 290

- Joined: Tue Apr 19, 2011 9:57 pm

Re: Shackleton WR963

Well as you have probably noticed, Cluny and I really enjoyed the spectacle of a LIVE Shackleton, she does indeed look absolutely wonderful and is a great credit to the team that have done so much already.

So at 13:00 and with VIPs aboard, START No3 was signaled.

Power was brought up……..

And the bomb doors were exercised revealing that capacious bomb bay.

Just look at the power as 3 and 4 come up to speed.

No1 comes alive.

She lives…….

THANK YOU for a CRACKING SPECTACLE!

So at 13:00 and with VIPs aboard, START No3 was signaled.

Power was brought up……..

And the bomb doors were exercised revealing that capacious bomb bay.

Just look at the power as 3 and 4 come up to speed.

No1 comes alive.

She lives…….

THANK YOU for a CRACKING SPECTACLE!

"All modern aircraft have 4 dimensions: span, length, height and politics.

TSR-2 simply got the first 3 right. ”

— Sir Sydney Camm

TSR-2 simply got the first 3 right. ”

— Sir Sydney Camm

-

Xplumberlives - Boeing B-17 Flying Fortress

- Posts: 41162

- Joined: Wed Oct 01, 2008 9:27 pm

- Location: Close to a former Harrier Airfield

- Also Known As: ROCKETMAN

Re: Shackleton WR963

I love that last low shot!

Cheers for keeping her going all those years, and to such a high standard. If she hadn't been that well maintained by the guys on the real 8 Sqn then she wouldn't have made it as far as she has now.

then she wouldn't have made it as far as she has now.

Come and see her any Saturday, you'll be most welcome.

Regards,

Rich

LightningMk6 wrote:Great pictures, brings back a few memories, especially the griffons, used to sit up there, cowlings hinged, checking out mag problems, drying off wet denims as the aircraft had just landed. 8 Squadron 74-76, Lossiemouth.

Cheers for keeping her going all those years, and to such a high standard. If she hadn't been that well maintained by the guys on the real 8 Sqn

then she wouldn't have made it as far as she has now.

then she wouldn't have made it as far as she has now.Come and see her any Saturday, you'll be most welcome.

Regards,

Rich

http://www.avroshackleton.co.uk/

http://www.facebook.com/ShackletonReturnToFlight

Follow our efforts to get a Shackleton back in the air!

http://www.facebook.com/ShackletonReturnToFlight

Follow our efforts to get a Shackleton back in the air!

-

Richw_82 - Lockheed F-104 Starfighter

- Posts: 290

- Joined: Tue Apr 19, 2011 9:57 pm

Return to Restoration and Preservation News

Who is online

Users browsing this forum: No registered users and 7 guests